GATE 2017-2018 :: GATE Production

- A milk vendor incurs an overstocking cost of Rs. 2 per litre and a shortage cost of Rs. 0.5 per litre. The demand is uniformly distributed between 1 litre and 6 litres. Using the Newsvendor Model, the maximum quantity of milk in litre(s) the vendor should order is

- The specification limits for the weight of a product are 13.1 kg and 15 kg. If the process has a variance of weight 0.05 kg2, then the process capability index is

- On an average, there are 30 customers in a queue. If the arrival rate of customers into the system is 16 customers per hour and on average 32 customers leave the system per hour, then the average number of customers in the system is

-

Data for four jobs that need to be processed on a single machine are given below.Job P Q R SProcessing time (days) 12 9 21 10Due date (days) 20 40 30 19All the four jobs are available at time zero. If the jobs are scheduled using the Earliest Due Date (EDD) algorithm, then the job with maximum tardiness is

-

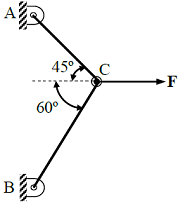

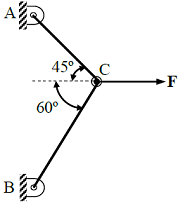

Two steel truss members, AC and BC, each having cross sectional area of 100 mm2, are subjected to a horizontal force F as shown in figure. All the joints are hinged.The maximum force F in kN that can be applied at C such that the axial stress in any of the truss members DOES NOT exceed 100 MPa is

-

Two steel truss members, AC and BC, each having cross sectional area of 100 mm2, are subjected to a horizontal force F as shown in figure. All the joints are hinged.If F = 1 kN, the magnitude of the vertical reaction force developed at the point B in kN is

-

Data for a plain milling operation are given below.Length of workpiece 200 mmCutter diameter 100 mmNo. of teeth 4Cutter speed 100 rpmFeed 200 mm/minDepth of cut 2 mmTotal clearance (entry 5 mmand exit)Mean undeformed chip thickness (in microns) is

-

Data for a plain milling operation are given below.Length of workpiece 200 mmCutter diameter 100 mmNo. of teeth 4Cutter speed 100 rpmFeed 200 mm/minDepth of cut 2 mmTotal clearance (entry 5 mmand exit)Machining time for a single pass (in seconds) is

-

In an EDM process using RC relaxation circuit, a 12 mm diameter through hole is made in a steel plate of 50 mm thickness using a graphite tool and kerosene as dielectric. Assume discharge time to be negligible. Machining is carried out under the following conditions:Resistance 40 ΩCapacitance 20 μFSupply voltage 220 VDischarge voltage 110 VThe time for one cycle, in milliseconds, is

-

In an EDM process using RC relaxation circuit, a 12 mm diameter through hole is made in a steel plate of 50 mm thickness using a graphite tool and kerosene as dielectric. Assume discharge time to be negligible. Machining is carried out under the following conditions:Resistance 40 ΩCapacitance 20 μFSupply voltage 220 VDischarge voltage 110 VAverage power input (in kW) is

Whatsapp

Whatsapp

Facebook

Facebook