GATE 2017-2018 :: GATE Production

- An ideal gas of mass m and temperature T1 undergoes a reversible isothermal process from an initial pressure P1 to final pressure P2. The heat loss during the process is Q. The entropy change ∆S of the gas is

- For an opaque surface, the absorptivity (α), transmissivity (t) and reflectivity (Ï) are related by the equation:

- Which one of the following configurations has the highest fin effectiveness?

- Oil flows through a 200 mm diameter horizontal cast iron pipe (friction factor, f = 0.0225) of length 500 m. The volumetric flow rate is 0.2 m3/s. The head loss (in m) due to friction is (assume g = 9.81 m/s2)

-

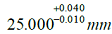

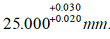

In an interchangeable assembly, shafts of size

mate with holes of size

mate with holes of size  . The maximum interference (in microns) in the assembly is

. The maximum interference (in microns) in the assembly is - A CNC vertical milling machine has to cut a straight slot of 10 mm width and 2 mm depth by a cutter of 10 mm diameter between points (0, 0) and (100, 100) on the XY plane (dimensions in mm). The feed rate used for milling is 50 mm/min. Milling time for the slot (in seconds) is

-

Match the following metal forming processes with their associated stresses in the workpiece.Metal forming process Type of stress1. Coining P. Tensile2. Wire Drawing Q. Shear3. Blanking R. Tensile and compressive4. Deep Drawing S. Compressive

- During normalizing process of steel, the specimen is heated

- In abrasive jet machining, as the distance between the nozzle tip and the work surface increases, the material removal rate

- Which one of the following is NOT a decision taken during the aggregate production planning stage?

Whatsapp

Whatsapp

Facebook

Facebook