GATE 2017-2018 :: GATE Production

- In simple exponential smoothing forecasting, to give higher weightage to recent demand information, the smoothing constant must be close to

- A company manufactures 1000 toys every day. On an average, 10% of the toys are defective and 40% of the defective toys can be reworked into defect-free ones. The average number of defect-free toys manufactured daily is

- The type of control chart used to monitor the amount of dispersion in a sample is

- Which one of the following is modeled based on adaptation capabilities of biological systems?

-

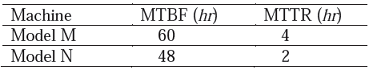

A company plans to purchase a machine whose uptime needs to be atleast 95%. They have shortlisted two models of the machine with the following operational characteristics:

The company should buy

The company should buy - A manufacturer produces bars designed to be of 10 mm diameter with a tolerance of ±0.1 mm. Historical data indicates that manufactured bars have an average diameter of 9.98 mm with a standard deviation of 0.15 mm. The process capability index is

- Let (P) denote the linear programming formulation of a transportation problem with m sources and n destinations. Then, the dual linear program of (P) has

-

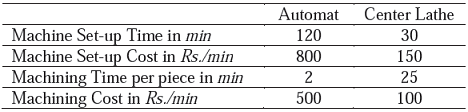

Following data refers to an automat and a center lathe, which are being compared to machine a batch of parts in a manufacturing shop.

Automat will be economical if the batch size exceeds

Automat will be economical if the batch size exceeds -

Cylindrical pins of

mm diameter are electroplated in a shop. Thickness of the plating is 30±2.0 micron. Neglecting gage tolerances, the size of the GO gage in mm to inspect the plated components is

mm diameter are electroplated in a shop. Thickness of the plating is 30±2.0 micron. Neglecting gage tolerances, the size of the GO gage in mm to inspect the plated components is - During the electrochemical machining (ECM) of iron (atomic weight = 56, valency = 2) at current of 1000 A with 90% current efficiency, the material removal rate was observed to be 0.26 gm/s. If Titanium (atomic weight = 48, valency = 3) is machined by the ECM process at the current of 2000 A with 90% current efficiency, the expected material removal rate in gm/s will be

Whatsapp

Whatsapp

Facebook

Facebook