Chemical Engineering :: Process Equipment and Plant Design

-

In case of a shell and tube heat exchanger, the minimum shell thickness for carbon steel (inclusive of corrosion allowance) depends on shell diameter and is in the range of __________ mm.

-

The stress developed in a material without any permanent set is called the

-

In a shell and tube heat exchanger, the 'tube pitch' is defined as the

-

Which of the following is not a valid assumption in continuous binary distillation for calculating the number of equilibrium stages by Mc-Cabe-Thiele's method ?

-

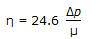

Overall distillation column efficiency for most of the refinery columns can be given by (for μ = 0.07 - 1.4 cp and relative volatility < 4) (where η = overall column efficiency, % μ = molal average viscosity of feed at average column temperature and pressure, cp Δp = pressure drop per tray, psi)

-

The value of fouling factor depends upon the

-

In case of bubble cap distillation column of diameter greater than 1.2 metres, the cap diameter is roughly about __________ cms.

-

Tube side pressure drop in a 1-2 heat exchanger (for turbulent flow of fluids through the tubes) is about __________ times, that in a 1-1 heat exchanger having the same size & number of tubes and operated at the same liquid flow rate.

-

To keep the power input constant for a stirred vessel operating under fully developed turbulent flow conditions (constant power number), if the impeller diameter is increased by 20%, the impeller speed should be decreased by a factor of

-

In a heat exchanger, shell side fluid velocity can be changed by changing the tube

Whatsapp

Whatsapp

Facebook

Facebook