Chemical Engineering :: Chemical Engineering Basics

-

The thickness of oxide film is y at time t. If K1, K2 and K3 are the temperature dependent constants, the parabolic law of oxidation is given by

-

Which of the following has the least value of ultimate tensile strength (UTS) ?

-

Which of the following is a commonly used manometric liquid for low pressure range?

-

The highest stress that a material can withstand for a specified length of time without excessive deformation is called the __________ strength.

-

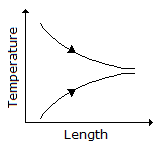

Temperature profile along the length of a gas-gas counter flow heat exchanger is correctly represented by

-

At the point of boundary layer separation in fluid flow, the

-

Brinell Hardness Number (BHN) for talc is approximately in the range of

-

A spring material should have low

Whatsapp

Whatsapp

Facebook

Facebook