Civil Engineering :: Water Supply Engineering

-

Most commonly used pump for lifting water in water supply mains, is

-

Economic height of a dam is the height corresponding to which

-

Distribution mains of any water supply, is normally designed for its average daily requirement

-

If pH value of water is

-

In pressure supply mains, water hammer pressure is reduced by providing

-

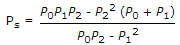

P0, P1, P2 be the populations of a city at times t0, t1 and t2 = 2t1, the saturation value of the population Ps of the city, is

-

Water supply system includes

-

Corrosion of a pipe

-

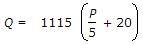

Most satisfactory formula for an estimate of fire demand Q for a city of population P in thousands for Indian conditions, is

-

Pick up the correct statement from the following :

Whatsapp

Whatsapp

Facebook

Facebook